- Get link

- X

- Other Apps

Understanding The Concept Of Electromagnetic Levitation As A Technological Evidence That Magnet Can Perform A Useful Work

- Get link

- X

- Other Apps

At certain times in our lives, we played around with magnets. During those times, you may have noticed when you used a magnet to lift another magnet in the air without them attracting. Although the magnet that was lifted in the air did not last long in the air before falling, the process worked a bit.

You may have seen some video clips where the earth is floating in the air. Have you taken some time to understand the concept behind it? Therefore, the theory behind floating a magnet in the air with another above it for some time and the earth floating in the air is through magnetic levitation.

So, in this article, we will explain the concept of electromagnetic levitation and its real-world applications.

READ ALSO: Hydro Power Generation and Aquatic Life Protection

What is magnetic levitation?

Magnetic levitation (maglev) or magnetic suspension is a method of suspending an object in the air without any support other than magnetic fields. The magnetic fields are used to oppose the effects of gravitational acceleration and any other opposing acceleration.

Magnetic levitation dates back to more than 100 years ago. During that period, two American scientists, Robert Goddard and Emile Bachelet developed frictionless trains.

For magnetic levitation to occur, two components are involved. These components include lifting forces and stability. Lifting forces provide an upward force that can oppose gravitational acceleration. Then, stability will ensure that the object does not automatically fall into a configuration where the lift is neutralized.

Magnetic levitation has the ability to create efficient, frictionless, and extraordinary technologies. The concept of maglev is popular in the design of magnetically levitated trains, however, the technology is not limited to this alone.

Concept of Electromagnetic Levitation

Now let us go back to when we used a magnet to lift another magnet by making it float in the air. You may have thought that it was magic that made it work, right? But it is not.

Since the unlike poles of two magnets repel each other, it can be possible to lift the magnet below with the repelling force of the magnet above.

Keep in mind that two things are required for electromagnetic levitation to occur: lifting forces and stability. Having enough force to lift and float the magnet in the air is not the problem however the problem is maintaining the stability of the lifted object in the air.

According to Earnshaw's theorem, it cannot be possible for a static system to float stably in the air (against gravity) when only paramagnetic materials are used. This is because the forces acting on any paramagnetic system in combination with either gravitational, electrostatic, and magnetostatic fields will make the position of the system to be unstable along at least one axis. The system can also be in unstable equilibrium along all axes.

READ ALSO: Horizontal Wind Turbine As Alternative Wind Breaker Of 21th Century

To achieve stability, servomechanisms, diamagnetic materials, superconduction, or systems involving eddy current are utilized.

Meanwhile, levitation and control of the six axes can be achieved by using a combination of permanent magnets and electromagnets or diamagnets, or superconductors, and attractive and repulsive fields. These six axes include degrees of freedom, 3 translational, and 3 rotational.

Methods of Electromagnetic Levitation

The two methods of levitation that are utilized in maglev trains include servo-stabilized Electromagnetic Suspension (EMS) and Electrodynamic Suspension (EDS).

READ ALSO: Bio septic tank and it's advantages in gas and fertilizer production

Electromagnetic Suspension (EMS)

You can make an object levitate or float stably by measuring the position and speed of the object that you are floating and using a feedback loop that will keep adjusting one or more electromagnets to correct the motion of the object. This method is called servomechanism.

Several systems are pulled up using magnetic forces against gravity and this gives them stability in the air. However, other systems are pulled upwards using a combination of magnetic attraction and magnetic repulsion.

The two systems above are examples of ElectroMagnetic Suspension (EMS). Cases, where the EMS is utilized, include tabletop demonstrations where the object cuts a light beam or the Hall effect sensor that measures the position of the object cutting the light beam.

In this setup, an electromagnet is placed above the object to be levitated. If the object gets too close to the electromagnet, the electromagnet will be turned off and once the object wants to fall away, the electromagnet is turned on. This is an example of Electromagnetic Suspension (EMS).

Furthermore, this type of levitation (Electromagnetic Suspension) is applied in the manufacture of maglev trains. Here, the maglev train wraps around the railway track and is pulled upwards from below as it moves. A distance is maintained between the train and its track by the servo controls.

Electrodynamic Suspension (EDS)

Electrodynamic suspension (EDS) involves exposing conductors to time-varying magnetic fields. When this is done, eddy currents will be induced in the conductors thereby creating a repulsive magnetic field that separates the two objects.

The motion between the two objects causes the time-varying magnetic fields. On several occasions, one of the magnetic fields is a permanent field (permanent magnet or a superconducting magnet) while the other magnetic field is induced due to the changes of the field that occur as the magnet moves relative to a conductor in the second object.

This method of magnetic levitation can also occur when an electromagnet that is controlled by an AC electrical source produces the changing magnetic field.

The different types of Electrodynamic Suspension (EDS) include Bedford levitator, levitation melting, linear induction motor, null flux, inductrack, and electrodynamic bearing.

Electrodynamic Suspension (EDS) is utilized in the design of maglev trains including the Japanese SCMaglev.

READ ALSO: Autonomous Mini Hybrid Hydro Power Plant

Applications of Electromagnetic Levitation

The use of upward magnetic forces to balance the constant downward force of gravity, i.e magnetic levitation, is applied in science and technology for different purposes.

Electromagnetic levitation is applied in the following:

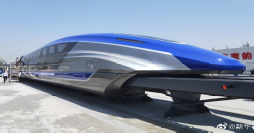

Magnetically Levitated Trains

The operation of magnetically levitated trains is the most important application of maglev. These trains are the most recent advancement in railway engineering and in the transportation industry. Its application has attracted several transportation industries worldwide for offering a solution to transportation needs.

Maglev is the first major innovation since railroad invention in railroad technology. The maglev train is a modern vehicle that uses non-contact magnetic levitation, guidance, propulsion systems without wheels, axles, and transmission.

Unlike traditional railroad trains, maglev trains have no physical contact with their guideway. It moves along magnetic fields that are induced between the train and its guideway. The maglev train moves very fast as it has recorded speed of travel equal to 581 km/hr.

Launching Rockets

NASA’s Marshall Space Flight Center is using magnetic levitation track technology at the moment. The center is developing a maglev technology that could power a space launch vehicle so that it can oppose the gravity of the earth. This system will utilize magnetic fields to float and accelerate a vehicle along a track at a speed of 600 mph. If this system is developed, it will reduce the cost of getting to space. Unlike rocket fuel that adds weight and it is expensive to launch a vehicle, the vehicle is powered by electricity which is a cost-expensive source of energy.

Maglev Fan

The concept of maglev technology is applied in the design of a maglev fan. Its design is based on magnetic principles and forces that will propel the fan and make it rotate stably in 360 degrees movement. In addition, the fan does not have friction as there is no contact between the shaft and bearing.

The maglev fan solves the problems of noise, vibration, and short service life that is common with traditional fan motors.

This fan is used in different industries and products that require high-level heat transfer including notebook computers, servers, projectors, and stereo systems.

Maglev Heat Pump

One of the major causes of premature death is heart failure. Patients that have heart failure are usually treated through heart transplantation, ventricular mechanical assistance, artificial organs substitution, etc.

The traditional heart pumps use rolling or sliding bearings and the blood gets polluted sometimes due to the contact between bearing and blood. However, maglev technology is applied in the design of artificial heart pumps that solves the problems of contact between bearing and blood, sealing, and lubrication. This will help to reduce the rate at which blood cells are damaged and improve heart pump life.

READ ALSO: CIRCUIT CONFORMING THE REALITY OF FREE ENERGY FROM IONIC GRAVITY

Analyzing Food and Beverages

In industries, the density of substances is measured to determine their chemical composition. For example, the measurement of density determines the sugar content in soft drinks, the percentage of alcohol in drinks, etc. Devices that carry out these measurements are no longer ideal as there needs to improvement.

Therefore, scientists have used the concept of maglev to develop a special sensor whereby solid or liquid samples are suspended using magnets to measure their density. This sensor has the shape of an ice cube. It is a container that is filled with fluid and magnets are placed at both ends.

Once a material is placed inside the container, the distance that the material will move determines its density. The device could also evaluate the salt content of different water samples and the fat content in different kinds of milk, cheese, and peanut butter.

Presently, there is ongoing research on this device to assess the suitability of water for drinking or irrigation, the fat content in foods and beverages, and controlling the processing of grains.

References

Comments

Post a Comment